scroll saw blade size guide

Scroll Saw Blade Size Guide: A Comprehensive Overview (Updated 02/12/2026)

Navigating the world of scroll saw blades requires understanding size factors; this guide details choosing the correct blade for optimal results and precision cutting.

Scroll saw blades are the heart of intricate woodworking, enabling detailed cuts that other saws simply can’t achieve. Selecting the appropriate blade isn’t merely about fit; it’s about unlocking the full potential of your scroll saw and achieving clean, precise results. The right blade dramatically impacts cut quality, speed, and even the longevity of both the blade and your workpiece.

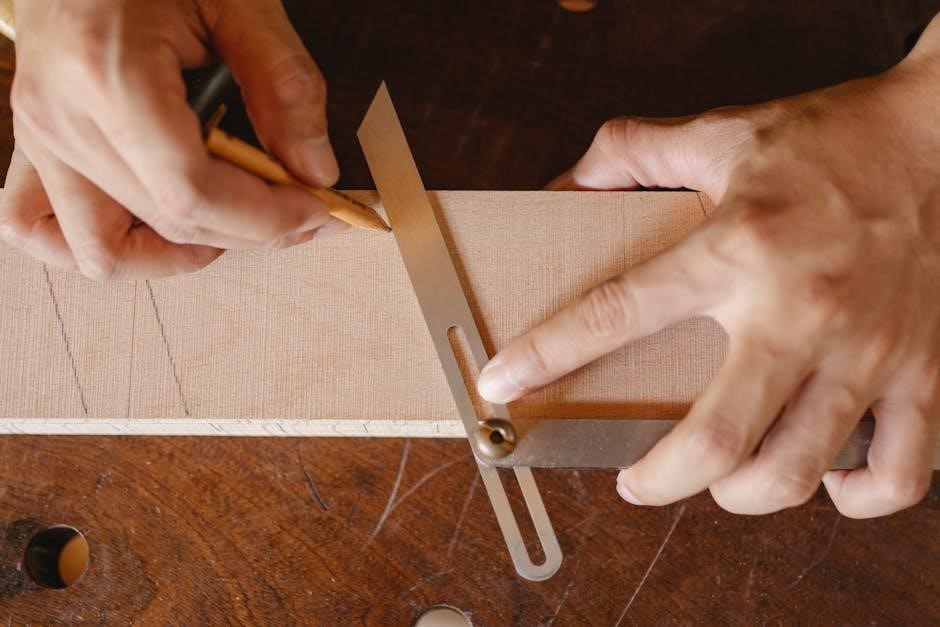

Understanding blade size – encompassing length, thickness (gauge), and teeth per inch (TPI) – is fundamental. These three characteristics work in harmony to dictate a blade’s performance with different materials and design complexities. This guide will demystify these elements, providing a comprehensive overview to empower both novice and experienced woodworkers. We’ll explore how each factor influences maneuverability, material compatibility, and the level of detail attainable in your projects. Choosing wisely ensures a smooth, efficient, and enjoyable scroll sawing experience.

Understanding Blade Length

Blade length on a scroll saw dictates the maximum thickness of material you can cut, as well as influencing maneuverability during intricate designs. Longer blades offer greater cutting capacity, allowing you to tackle thicker stock, but they can be more prone to bending or breaking during tight turns. Conversely, shorter blades excel at detail work and navigating complex curves, but are limited in the thickness they can handle.

The exposed portion of the blade, measured from the clamp to the bottom of the saw table, is the critical dimension. A sufficient blade length ensures the material can pass freely beneath the blade without obstruction. Selecting the correct length is a balance between cutting capacity and control; always prioritize a length appropriate for your project’s specific needs and the material’s thickness.

Standard Scroll Saw Blade Lengths

Common scroll saw blade lengths typically range from 2.5 inches to 13 inches, catering to diverse project requirements. Shorter blades, around 2.5 to 5 inches, are ideal for intricate detail work, tight curves, and thin materials. Mid-range blades, spanning 6 to 9 inches, offer a versatile balance for general-purpose cutting and moderate material thicknesses.

Longer blades, from 9 to 13 inches, are best suited for cutting thicker stock, providing the necessary reach and stability. Many manufacturers offer blades in incremental sizes within these ranges, allowing for fine-tuning based on specific needs. It’s crucial to check your scroll saw’s manual for its maximum blade length capacity to ensure compatibility and safe operation. Selecting the right length optimizes performance and prevents damage.

Blade Length and Cutting Capacity

The relationship between blade length and cutting capacity is directly proportional; a longer blade allows for cutting thicker materials. However, exceeding your scroll saw’s throat depth with an overly long blade can cause binding and potential damage. The throat depth is the distance from the blade clamp to the back of the saw’s table.

Generally, a blade should extend at least 1 inch beyond the material’s thickness to ensure smooth cutting. Longer blades also provide more stability when cutting thicker stock, reducing blade wander. Conversely, using a blade that’s too short for the material’s thickness can lead to inefficient cutting and a rough edge. Always prioritize a blade length that balances cutting capacity with safe and effective operation within your saw’s specifications.

The Impact of Blade Length on Maneuverability

Blade length significantly impacts maneuverability, especially when tackling intricate designs. Shorter blades offer greater control for tight curves and detailed work, responding quicker to directional changes. However, their limited length restricts the thickness of material they can effectively cut.

Longer blades, while capable of handling thicker materials, can be more challenging to maneuver through complex patterns. They possess more inertia, requiring a steadier hand and slower feed rate. Finding the right balance is crucial; a blade too long hinders detail work, while one too short limits project possibilities. Consider the complexity of your design and material thickness when selecting a blade length to optimize both control and cutting capacity.

Decoding Blade Thickness (Gauge)

Blade thickness, measured in gauge, is a critical factor influencing cutting performance and blade durability. A lower gauge number indicates a thicker blade, offering greater rigidity and resistance to bending, making them ideal for cutting thicker materials and reducing blade breakage during demanding cuts. However, thicker blades remove more material, creating a wider kerf.

Conversely, higher gauge numbers represent thinner blades, providing finer cuts with a narrower kerf, perfect for intricate details and minimizing material waste. These blades are more flexible but are prone to bending or snapping when used on thicker stock or with excessive force. Understanding the gauge system allows you to select a blade that balances strength, precision, and material compatibility for optimal results.

Blade Thickness and Material Compatibility

Selecting the appropriate blade thickness, or gauge, is intrinsically linked to the material you intend to cut. Thicker blades excel when tackling hardwoods like oak or maple, and even non-wood materials such as thicker plastics, providing the necessary strength to power through dense substances without buckling or breaking. Their robustness handles the increased resistance.

Conversely, thinner blades are best suited for softer woods like pine or basswood, as well as delicate materials like thin acrylics. Using a thick blade on these softer materials can lead to splintering and rough edges. Matching blade thickness to material density ensures clean, precise cuts, minimizes blade damage, and optimizes the overall cutting experience, resulting in professional-quality results.

Choosing the Right Gauge for Different Woods

Determining the ideal blade gauge hinges on the wood’s hardness and thickness. For hardwoods – maple, oak, walnut – a thicker gauge (typically 0.017” to 0.025”) provides the necessary rigidity to prevent bending during cuts. These woods demand more force, and a robust blade maintains accuracy.

Softwoods like pine, cedar, and poplar require a thinner gauge (0.010” to 0.015”). A lighter touch is sufficient, and thinner blades minimize splintering and deliver cleaner edges. Medium-density woods, such as cherry or birch, benefit from an intermediate gauge (0.015” to 0.019”). Always consider the intricacy of the design; detailed work often favors a slightly thinner blade within the appropriate range for the wood type.

Relationship Between Gauge and Detail

The blade gauge profoundly impacts the level of detail achievable in scroll saw work. Thinner blades, with their reduced kerf (width of the cut), allow for tighter turns and more intricate designs. However, this comes at a cost – thinner blades are more prone to wandering or breaking, especially in thicker or harder materials.

Conversely, thicker blades offer greater stability and are less likely to deflect, but they limit the sharpness of internal corners and the fineness of detail; A balance must be struck. For highly detailed projects, prioritize a thinner gauge, accepting the need for slower speeds and careful control. For simpler designs or thicker stock, a thicker gauge provides robustness and efficiency.

Common Blade Thicknesses Explained

Scroll saw blades are categorized by their thickness, measured in gauge – a numerical system where a higher number indicates a thicker blade. Common thicknesses range from 0/0 (very fine) to 30 (relatively thick). A 0/0 blade, around 0.009 inches, is ideal for extremely delicate work in thin materials like veneer or thin plastics, demanding precision and control.

The 2/0 blade (approximately 0.011 inches) is a versatile all-rounder, suitable for many projects. Blades in the 1-10 gauge range (0.012 – 0.024 inches) are used for progressively thicker materials and less intricate designs. Finally, gauges 15-30 are reserved for heavier-duty cutting, like thicker hardwoods or non-wood materials, prioritizing durability over fine detail.

Tooth Per Inch (TPI) Explained

Tooth Per Inch (TPI) defines the number of teeth along one inch of the blade, significantly impacting cutting performance. Higher TPI blades (e.g., 35 TPI) possess more teeth, resulting in smoother cuts and finer detail, but slower cutting speeds. These are best suited for intricate curves and delicate materials.

Lower TPI blades (e.g., 10 TPI) have fewer, larger teeth, enabling faster cutting through thicker materials. However, they produce a rougher edge and are less effective for tight curves. The ideal TPI depends on the material’s hardness and thickness, as well as the desired finish and complexity of the cut; Selecting the correct TPI is crucial for efficient and clean scroll saw operation.

TPI and Cutting Speed

The relationship between Teeth Per Inch (TPI) and cutting speed is inversely proportional. Blades with a higher TPI, while delivering smoother finishes and intricate detail, inherently cut slower. This is because each tooth removes a smaller amount of material with each pass.

Conversely, lower TPI blades, featuring fewer but larger teeth, excel at rapid material removal, leading to faster cutting speeds. However, this speed comes at the cost of finish quality and precision. For quick, rough cuts in softer woods, a lower TPI is preferable. For detailed work in hardwoods, prioritizing a higher TPI, despite the slower pace, yields superior results. Balancing speed and quality is key to effective scroll sawing.

TPI for Hardwoods vs. Softwoods

Selecting the appropriate TPI hinges significantly on the wood’s density. Hardwoods, like oak, maple, and walnut, demand higher TPI blades – typically ranging from 10 to 15 TPI. This finer tooth count allows for cleaner cuts through the dense fibers, minimizing tear-out and achieving smoother edges. The increased resistance of hardwoods necessitates more cutting edges per inch.

Softwoods, such as pine, cedar, and fir, require fewer teeth per inch, generally between 6 to 10 TPI. Their softer composition allows for quicker material removal with coarser blades. Using a high TPI blade on softwood can lead to excessive friction, heat buildup, and a sluggish cutting experience. Matching the TPI to the wood’s density optimizes both speed and finish.

TPI for Intricate Designs

When tackling detailed scroll saw work, a higher TPI blade is paramount. Intricate designs, characterized by tight curves and delicate features, benefit immensely from blades boasting 15 TPI or even higher – reaching up to 20 TPI for exceptionally fine work. These finer teeth allow for precise maneuvering within the design, minimizing chipping and ensuring clean, crisp lines.

The smaller kerf (width of the cut) produced by higher TPI blades also preserves more of the material, crucial when working with limited stock or aiming for highly detailed results. However, remember that increased TPI equates to slower cutting speeds, so patience is key. Prioritize precision over speed when executing complex patterns.

Selecting TPI Based on Wood Thickness

Matching Tooth Per Inch (TPI) to wood thickness is crucial for efficient and clean cuts. Thicker wood demands fewer teeth per inch – typically 7-10 TPI – allowing for faster material removal and preventing the blade from becoming clogged with sawdust. Conversely, thinner wood requires a higher TPI, generally 10-15 TPI, to avoid splintering and ensure a smooth edge.

A good rule of thumb is to ensure at least three teeth are always engaged with the wood. Insufficient tooth engagement leads to blade wandering and rough cuts. For very thin veneers or delicate materials, specialized blades with exceptionally high TPI may be necessary. Always test on scrap wood first to confirm optimal TPI selection.

Blade Types and Their Sizes

Scroll saw blades come in various types, each suited for specific tasks. Pin end blades, the most common, feature a tang at each end for universal fit, typically ranging from 9 to 12 inches in length. Plain end blades require a scroll saw with a clamping mechanism, offering a secure hold and often found in shorter lengths, around 6-8 inches.

Spiral blades, available in lengths from 6 to 12 inches, cut in all directions, ideal for intricate curves. Reverse tooth blades, usually 9-12 inches, have teeth pointing upwards, minimizing splintering on the top surface. Skip tooth blades, commonly 9-12 inches, excel at fast, aggressive cuts in softer woods. Selecting the correct type significantly impacts cut quality and efficiency.

Pin End Blades vs. Plain End Blades

Pin end blades are the most widely used type, characterized by pins at both ends that fit into the scroll saw’s holding mechanism. They offer versatility and are readily available in lengths from 9 to 12 inches, making them suitable for a broad range of projects. Plain end blades, conversely, lack pins and require a scroll saw equipped with a clamping system to secure them.

Plain end blades, typically shorter, around 6-8 inches, provide a tighter grip and reduced vibration, enhancing precision. While requiring a specific scroll saw type, they are favored by experienced users for detailed work. The choice depends on your scroll saw’s capabilities and desired level of control.

Spiral Blades: Sizes and Applications

Spiral blades distinguish themselves with teeth that spiral along the blade’s length, enabling cuts in any direction without needing to rotate the workpiece. Commonly available in lengths ranging from 8 to 14 inches, they excel at cutting thick materials and creating smooth, flowing curves. Their unique design minimizes tear-out, resulting in cleaner edges.

Sizes typically refer to the overall blade length and the width of the blade itself. Wider blades are suited for thicker stock, while narrower blades offer tighter turns. Applications include intricate fretwork, shaping complex designs, and cutting materials like acrylic or thin metals. Spiral blades are a valuable addition to any scroll saw enthusiast’s collection, offering versatility and efficiency.

Reverse Tooth Blades: Sizes and Benefits

Reverse tooth blades feature teeth angled in the opposite direction of a standard blade, effectively acting as a miniature file during the upstroke. This unique configuration significantly reduces top-edge chipping and splintering, particularly crucial when working with delicate veneers, plywood, or laminated materials. They are generally available in lengths mirroring standard blades – typically 8 to 14 inches.

Sizes are selected based on material thickness and the intricacy of the cut. Benefits extend beyond cleaner cuts; they also minimize the need for extensive sanding or finishing. These blades are ideal for projects demanding a pristine edge quality, such as intarsia, marquetry, or detailed sign making. Utilizing reverse tooth blades elevates the final product’s professional appearance.

Skip Tooth Blades: Sizes and Uses

Skip tooth blades are characterized by a pattern of teeth with gaps, or “skips,” between them. This design excels at rapidly removing waste material, making them a superb choice for thicker stock and faster cutting speeds. Common lengths range from 8 to 14 inches, mirroring standard blade sizes, and are available in various tooth per inch (TPI) counts.

Uses for skip tooth blades are broad, encompassing rough cutting, shaping, and creating curves in wood up to ¾ inch thick. The gaps help clear debris efficiently, preventing clogging and maintaining consistent performance. While not ideal for ultra-fine detail, they are excellent for projects where speed and material removal are prioritized, like fretwork or basic silhouette cuts. They offer a balance between speed and control.

Blade Size Charts for Common Materials

Selecting the appropriate blade size hinges on the material being cut. For wood, a general guideline suggests using blades with 10-15 TPI for ¼ inch thickness, 12-18 TPI for ½ inch, and 15-20 TPI for ¾ inch or greater. Plastic and acrylic require finer teeth – 15-25 TPI – to prevent melting or chipping. Thinner materials necessitate higher TPI counts for clean edges.

Metal, particularly thin gauge sheet metal, demands specialized blades with 24-32 TPI and slower feed rates. Always prioritize a finer tooth count for smoother cuts and reduced burring. Remember these are starting points; experimentation is key. Consider the wood’s hardness – hardwoods need fewer TPI than softwoods. Charts are available online detailing specific recommendations for various materials and thicknesses, aiding in optimal blade selection.

Wood Thickness and Blade Size Recommendations

Matching blade size to wood thickness is crucial for clean cuts and preventing blade breakage. For woods up to ¼ inch thick, a blade with 10-15 teeth per inch (TPI) is generally recommended. Increasing the wood thickness to ½ inch calls for 12-18 TPI, offering a balance between speed and control.

Thicker woods, ¾ inch and beyond, benefit from 15-20 TPI blades, ensuring sufficient teeth are engaged for a stable cut. Hardwoods typically require fewer TPI than softwoods due to their density. Always err on the side of a higher TPI if unsure, as it produces a finer finish. Remember to adjust your cutting speed; slower speeds are vital for thicker materials and higher TPI blades, minimizing heat buildup and maximizing precision.

Plastic and Acrylic Cutting Blade Sizes

Cutting plastics and acrylics with a scroll saw demands specialized blade selection to avoid melting, chipping, or cracking. Finer tooth counts are essential; blades with 15-20 TPI are ideal for achieving smooth, clean edges. A slower cutting speed is paramount, as plastic generates heat quickly, potentially ruining the material and the blade.

Consider using blades specifically designed for plastics, often featuring a polished tooth set to reduce friction. Blade thickness isn’t as critical as TPI, but a thinner gauge can help minimize material removal. Experiment with different TPI within the recommended range to find the optimal balance between speed and finish quality for your specific plastic type and thickness. Lubrication, like water or a specialized cutting fluid, can further reduce heat.

Metal Cutting Blade Sizes (Thin Gauge)

Cutting metal with a scroll saw requires specialized blades and a deliberate approach. Only thin-gauge metals – think thin brass, copper, or aluminum sheeting – are suitable for scroll saw cutting. Blades with very fine teeth, typically 24-32 TPI, are crucial to prevent grabbing and ensure a clean cut. Lubrication is absolutely essential; use a cutting oil specifically designed for metal to reduce friction and heat buildup.

Blade material matters; high-speed steel (HSS) blades are the standard for metal cutting. Maintain a very slow feed rate and apply minimal pressure. Metal cutting generates significant heat, so frequent blade cooling and occasional pauses are necessary. Expect slower cutting speeds compared to wood or plastic, and be prepared to replace blades more often due to wear.

Troubleshooting Blade Size Issues

Encountering problems? Blade wandering often indicates an incorrect TPI for the material’s thickness or a dull blade. If the blade breaks frequently, you might be forcing the cut, using a blade too thin for the material, or the tension is incorrect. Excessive vibration suggests a dull blade, improper tension, or attempting to cut material too thick for the blade’s capacity.

Burning or melting, especially with synthetic materials, signals too much speed or insufficient lubrication. A rough cut edge usually points to a dull blade or an inappropriate TPI. Always double-check blade tension; too loose causes wandering, while too tight increases breakage risk. Regularly inspect blades for damage and replace them promptly to maintain optimal performance and prevent further issues.